In this article, the weld defect acceptance/rejection criteria are given for the following tests/NDT;

1. Acceptance criteria for Visual Inspection

(This article covers the weld defect acceptance criteria as per ASME Section VIII Div 1, which is one of the most widely used standards for acceptance criteria for weld defect

Acceptance criteria for Visual Inspection

(Refer: UIG-97, Page – 345 of ASME BPVC Section VIII Div 1, 2017 Edition.)

(a) The surface shall be free of any visible laminations, spalling, or cracks. Cracks in tubes shall not be repaired and shall be considered cause for rejection.

(b) For tubes, the depth of scratch shall not exceed 1/32 in. (0.8 mm). For all other material, the scratch depth shall not exceed 1/8 in. (3 mm).

For an acceptable limit of thickness reduction, Refer to UW-35 (sub-para b, page – 144) which states that:

- The reduction in thickness shall not exceed 1mm (1/32 in.) or 10% of material nominal thickness whichever is less, provided that the material of the adjoining surfaces below the design thickness at any point.

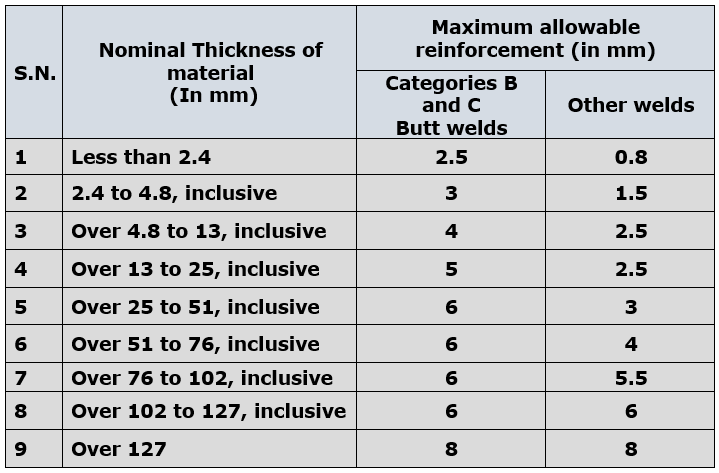

For the allowable limit of Weld Reinforcement (excess weld metal), Refer to UW-35 (sub-para d, Page – 144)